WHY MICROPOROUS TECHNOLOGY IS SUPERIOR FOR HIGH-TEMPERATURE APPLICATIONS

Our microporous insulation products achieve superior thermal performance by simultaneously tackling conduction, convection, and radiation. Its nano-porous fumed silica structure limits gas and solid conduction, while added opacifiers block radiative heat. This synergy creates an insulation with thermal conductivity near the theoretical limit of still air, maintaining efficacy in extreme environments.

Outstanding Thermal Performance: Extremely Low Thermal Conductivity at High Temperatures

Our microporous insulation features extremely low thermal conductivity across a wide temperature range. Combined with our diverse portfolio, it helps high-temperature applications achieve greater energy efficiency and carbon reduction.

| Classification |

1000℃ grade |

1050℃ grade |

1100℃ grade |

1200℃ grade |

| Thermal Conductivity (W/m·K) |

0.021 @ 20°C

0.023 @ 200°C

0.026 @ 400°C

0.030 @ 600°C

0.034 @ 800°C |

0.022 @ 20°C

0.025 @ 200°C

0.029 @ 400°C

0.032 @ 600°C

0.036 @ 800°C |

0.026 @ 20°C

0.029 @ 200°C

0.032 @ 400°C

0.035 @ 600°C

0.038 @ 800°C |

0.026 @ 20°C

0.029 @ 200°C

0.032 @ 400°C

0.035 @ 600°C

0.038 @ 800°C |

* The above data is based on our internal testing of standard samples and represents typical product performance. Detailed technical data sheets and test reports are available upon request.

Dimensional and Chemical Stability

Our microporous outstanding dimensional stability prevents thermal gaps, ensures consistent performance under cycling, and extends the operational life of thermal systems. The material’s fine-particle structure also offers excellent resistance to thermal shock and

oxidation, maintaining integrity even after repeated heating and cooling cycles.

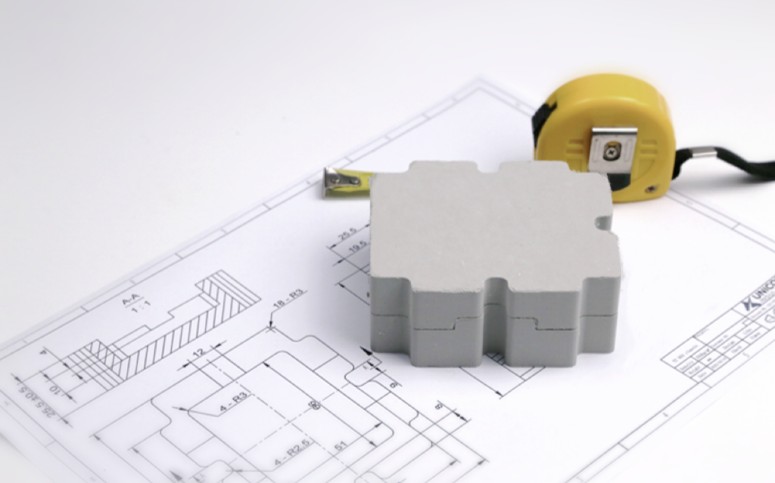

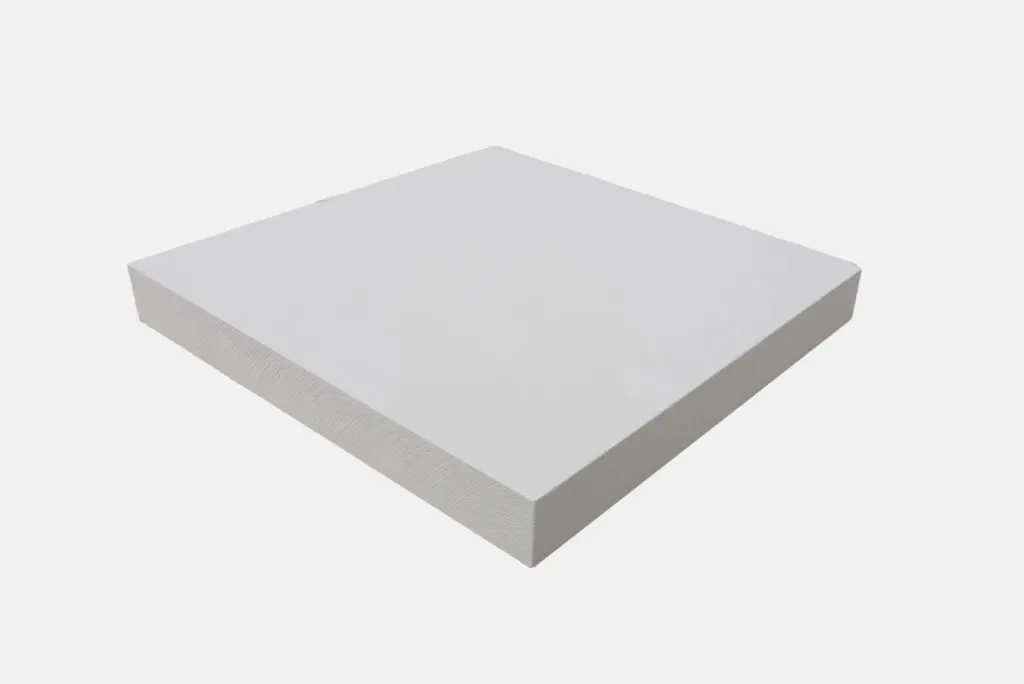

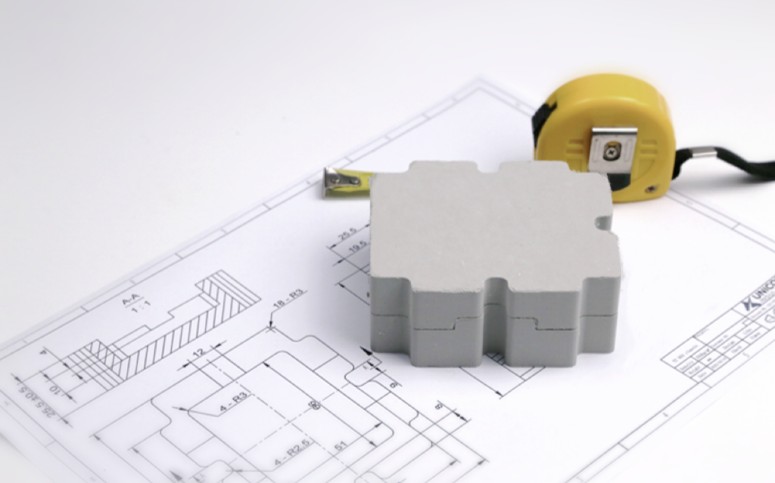

Versatile, Engineered Microporous Insulation

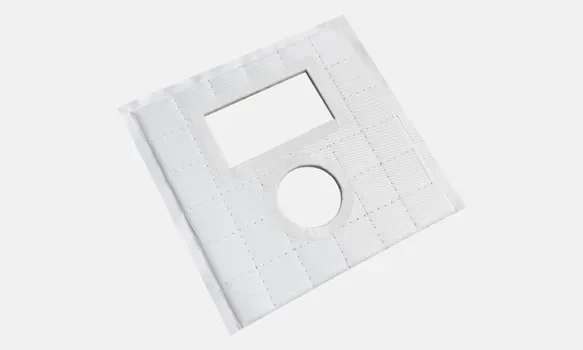

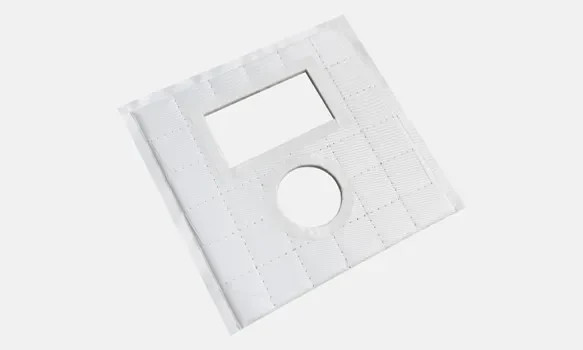

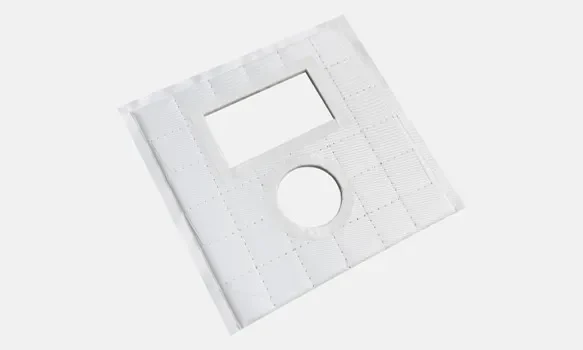

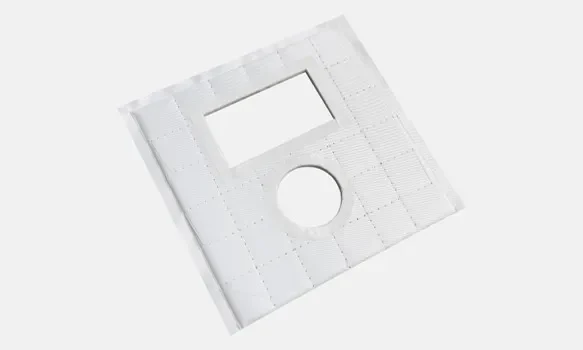

Our microporous insulation products with different shapes and processed styles are designed for versatile integration into complex thermal assemblies.

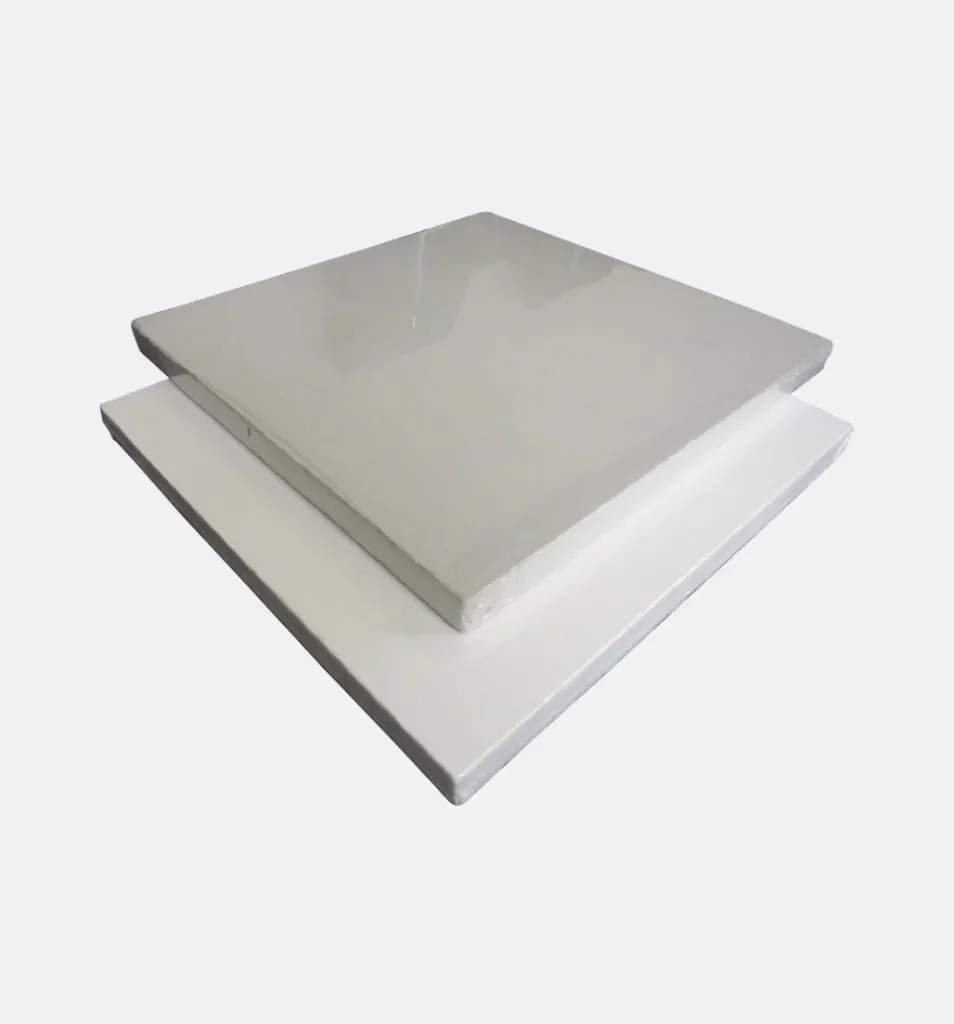

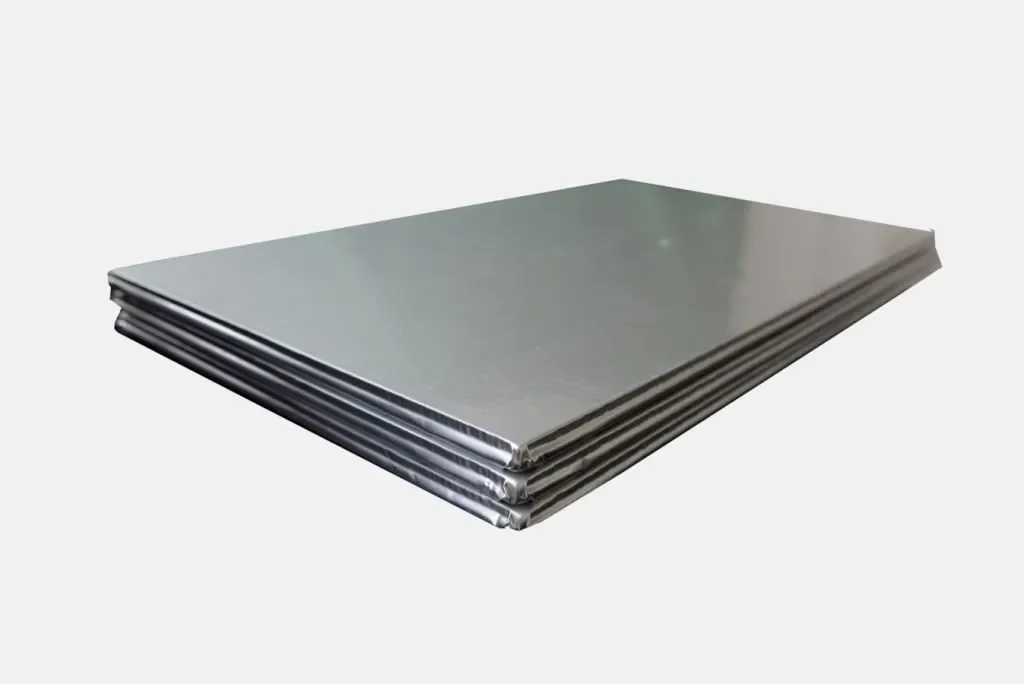

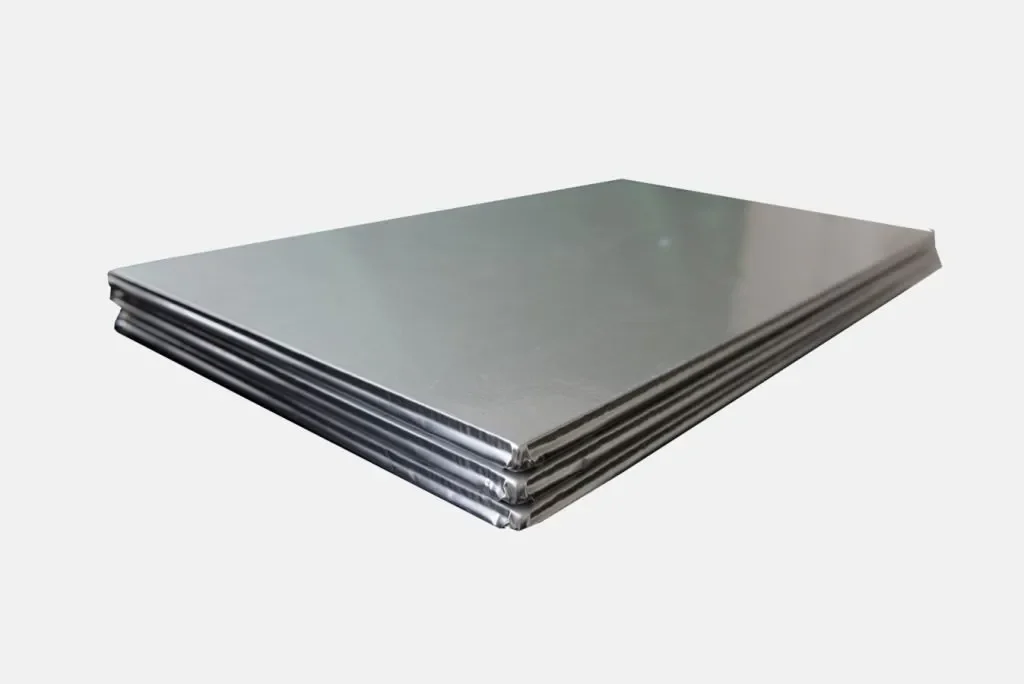

Board or panel-shaped products can be cut, drilled, or machined using standard woodworking tools. Board shaped products are available in naked, wrapped, or laminated forms (e.g., aluminum foil, glass tissue) to suit specific applications.

For large-scale production, custom molding and net-shape pressing help minimize waste and improve precision.

Our boards or panels can also be combined with other insulators to create multi-layer configurations — optimizing both performance and cost efficiency across different temperature zones within the same system.

Ecologically Effective Throughout the Entire Life Span

Our microporous insulation materials are free of organic binding agents. They are made of silica (silicon dioxide) or alumina, an inorganic opacifying agent, and non-hazardous fibres that are resistant to high temperatures. These inherently stable products are long-lasting, do not rot, are vermin-resistant and easy to recycle.